History

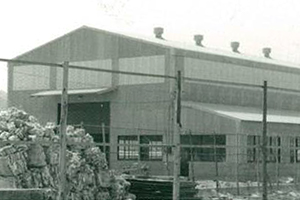

Azuma Ironworks reopens in Ōchi-chō Yokouchi, Ōkawa-gun, Kagawa Prefecture

Manufacturing, etc. of sugar press machines, agricultural equipment, and noodle-making machines

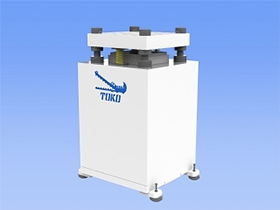

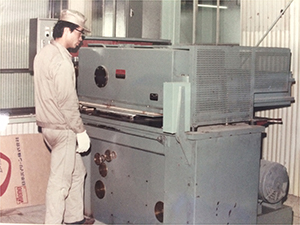

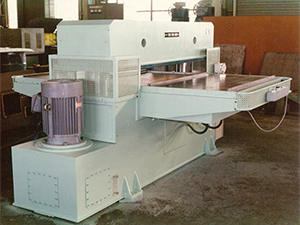

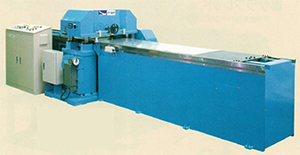

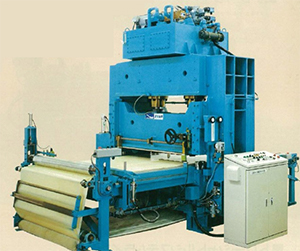

Production and sales of TCM-500 hydraulic clickers begins

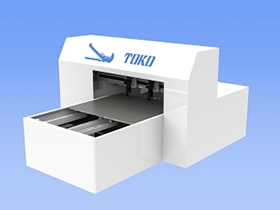

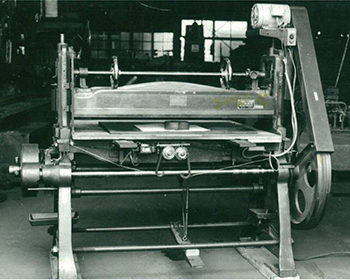

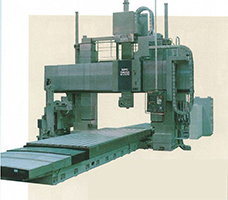

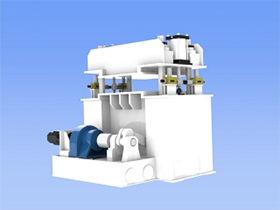

Production and sales of new models of compound planers (L15, L21) begins

In accordance with the Fourth Rationalization Plan, the adjacent site is purchased and the factory expanded

Tokyo Office becomes the TOKO Tokyo Branch Office

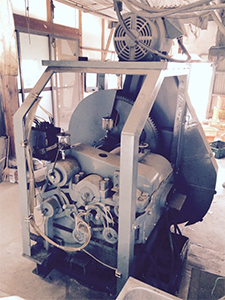

NC lathe compound machine is introduced